1. Correct understanding of four-row cylindrical roller bearings for rolling mills

Four-row cylindrical roller bearings used in rolling mills are mainly available as FC type (single inner ring), FCD type (double inner ring), and FCDP type (double inner ring with a flat retaining ring). They operate in severely harsh environments with heavy loads, high unit contact pressure, and significant heat generation; consequently their service life is relatively short and their characteristics differ markedly

from ordinary bearings.

From an application standpoint, roll bearings require good lubrication and cooling conditions and should have as small a radial envelope as possible. Bearings for different roll positions (for example, work rolls versus backup/support rolls) differ substantially in operating conditions and selection. Key application considerations include:

• Speed: design must balance the maximum operational speed and the ability to form a stable lubricant film at low speeds.

• High loads: uneven load distribution among multiple roller rows is common and individual rows can become non-load bearing.

• Inner/outer-ring eccentricity: affects clearance and therefore strip/sheet precision.

• Axial forces: these bearings are not intended to carry axial load and must be paired with thrust bearings.

• High temperatures: can cause lubricant failure and require special attention.

On the manufacturing side, bearing materials must provide high load capacity, low friction, impact resistance and good inclusion tolerance. Large-size bearings require specialized materials and processes; domestic capability for high-end, large-diameter bearings remains limited and key equipment still often depends on imports.

From the roll-set structural design viewpoint, a reasonable bearing arrangement is a prerequisite for both rolling-mill performance and normal bearing operation. As aluminum sheet/strip mills move toward higher speed, higher load, higher precision, and greater reliability, the configuration “four-row cylindrical roller bearing + thrust bearing” has become increasingly common. Its advantages include:

• Maximum radial load capacity for a given cross-sectional envelope;

• Separation of radial and axial load paths (radial carried by the cylindrical roller bearing, axial by the thrust bearing), enabling higher rolling speeds;

• More precise control of axial clearance, which helps improve product accuracy;

• High bearing precision and reliability;

• Separable inner and outer rings for easy roll assembly/disassembly;

• Tight fit between inner ring and roll neck to prevent relative rotation that can cause overheating;

• Easy maintenance and inspection, resulting in lower overall operating cost.

According to JB/T 5389.1-2005, rolling-mill bearing components are made from carburizing steels G20Cr2Ni4(A) or high-carbon chromium bearing steel GCr15(SiMn) and must meet the corresponding heat-treatment requirements. Given the working characteristics of rolling mills, a fixed service life is generally not specified for these bearings. For high-precision sheet/strip mills, to guarantee roll-set accuracy the inner-ring outer diameter is often supplied with machining allowance; after assembly to the roll body the inner ring and roll are ground together to the final dimension to ensure radial clearance and concentricity.

2. Correct use of four-row cylindrical roller bearings for rolling mills

The problems described above in current use and management shorten bearing life, reduce production stability, and make it difficult to guarantee product precision. Although rolling-mill bearings are not assigned a fixed life, manufacturers and users should strive to extend effective service life to reduce production cost. Apart from normal fatigue spalling, common failure modes include wear, scuffing (brinelling/burn damage), and lubricant degradation; these manifest as increased running resistance, rapid temperature rise, abnormal vibration and noise, or even seizure.

2.1 Failure modes and root-cause analysis

(1) Contact fatigue spalling

Aluminum sheet/strip mills often operate in reversible rolling modes. Bearings run under heavy load, high impact and alternating stress, so rolling-element surface fatigue spalling is common.

(2) Wear

There is both rolling and sliding friction inside the bearing; inadequate lubrication accelerates wear, enlarges internal clearance, and degrades precision. Mild wear may be tolerated, but if it compromises strip/sheet accuracy the bearing must be replaced immediately.

(3) Scuffing/burn damage

Rapid frictional heating can lead to lubricant failure and surface metallurgical changes or adhesive seizure. Improving bearing design, using self-lubricating cages, and strengthening cooling and lubrication systems are key preventive measures.

(4) Lubricant (grease/oil) failure

Grease degrades due to shear, oxidation, contamination and leakage, causing frictional heating and surface burn damage.

Major factors affecting bearing life include:

• Dynamic loads: impact loads are the principal cause of abnormal bearing damage. Operations should be regulated to avoid jamming, multilayering of material, and other abnormal conditions.

• Bearing material: composition and heat treatment have a significant influence on life and should be optimized with the manufacturer for the application.

• Installation and sealing: good concentricity, effective seals and correct clearance are foundational to long life.

• Pairing: maintain consistent pairing of bearings with specific rolls and housings; avoid indiscriminate regrinding of inner rings and ensure even load distribution.

• Lubrication: select appropriate lubricant type and supply method; avoid over- or under-lubrication and prevent ingress of contaminants.

2.2 Key points for correct use

2.2.1 Adopt the right mindset

Rolling-mill bearings operate under heavy loads (2–5× those of ordinary bearings), over a wide speed range, in harsh environments, with frequent roll changes and high precision requirements. They require low friction, compact radial envelopes, high precision and easy assembly/disassembly. They are suitable for work and backup rolls in four-high mills but must be used in conjunction with thrust bearings to carry axial loads.

2.2.2 Scientific clearance specification and strict pairing control

Radial clearance realization generally follows either a shaft-based (inner/ring) or housing-based (outer/ring) system. JB/T 5389.1-2005 recommends the housing-based (outer-ring basis) method, which is advantageous for batch production and quality control. Clearance magnitude directly affects internal load distribution and maximum roller load and must be determined taking fit, temperature rise and deformation into account. The radial and axial clearances of the radial bearing and the thrust bearing should be matched to avoid mutual interference.

When changing rolls, rotate the bearing outer ring by 90° periodically to even out wear and extend life. Establish bearing usage records and fix the pairing relationships between bearings, rolls and housings. Perform regular cleaning and inspections and judge replacement by clearance standards. Prefer original matched sets.

2.2.3 Standardize assembly/disassembly procedures

Many companies currently use overhead cranes to remove/fit bearing housings; this can cause alignment difficulties, low efficiency and risk of damage to roll necks and bearings. Specialized disassembly/assembly equipment has been promoted in the steel industry and copper processing plants should progressively adopt such equipment to achieve safe, efficient and precise operations. Although initial investment is high, long-term benefits are significant.

2.2.4 Standardize lubrication management

The purpose of lubrication is to separate metal surfaces with a lubricant film and reduce wear. Common practical problems include seal failure leading to grease contamination by emulsion coolant, ingress of emulsified coolant causing lubricant breakdown, and moisture producing corrosion and hydrogen embrittlement. Lubrication methods include grease lubrication and oil lubrication (oil mist, oil-air):

• Grease lubrication: suitable for small or simple mills. Use water-resistant lithium-base greases and select penetration (NLGI grade), viscosity and fill amount according to speed, temperature and environment (typically fill 1/3–1/2 of free space). Replenish and replace at intervals and never mix different grease brands.

• Oil-mist lubrication: compresses air to atomize lubricant and deliver it to the lubrication point. Advantages: uniform lubrication, good cooling, low oil consumption and some sealing effect. Disadvantages: the exhaust air contains oil mist that must be treated; the system depends on compressed air and is suitable only for low-viscosity oils; utilization efficiency is relatively low.

• Oil-air lubrication: mixes oil droplets with compressed air without atomization. Suitable for high speed, high temperature, heavy load and heavily contaminated environments. Can handle a range of oil viscosities; oil and air flow rates are adjustable. It is environmentally friendly, maintains slightly elevated internal pressures to resist contamination, but investment is larger.

2.2.5 Strengthen roll-set installation management

Mill operating conditions and roll-set assembly quality directly affect bearing life. Pay attention to:

• Regular inspection and adjustment of roll axis parallelism; use dedicated bearing housings and avoid interchange of housings;

• Timely replacement of worn drive components to reduce clearances that induce extra axial forces;

• Ensure bearing housings have an alignment/adjustment function to avoid eccentric loading;

• Check dimensional and geometric tolerances and fits of housings, guard windows and other related parts;

• Control roll bending (deflection) to avoid overload and uneven loading among roller rows;

• Standardize bearing and housing assembly:

– Inner-ring mounting: use induction or oil bath heating (≤120 °C); do not use open flame. After mounting, press the ring fully home and allow it to cool under axial restraint.

– Outer-ring mounting: lightly tap into seat, observe axial face markings, maintain original order and record loaded zones.

– Seal assembly: select appropriate seals (for example, fluoro-rubber lip seals) and install with correct lip orientation to prevent ingress of cooling fluid and contaminants.

Through systematic management, standardized procedures and continuous optimization it is possible to significantly improve the service life and reliability of four-row cylindrical roller bearings for rolling mills, thereby providing a solid foundation for high-quality sheet/strip production.

Thin Section Bearings

Thin Section Bearings heavy-duty bearings

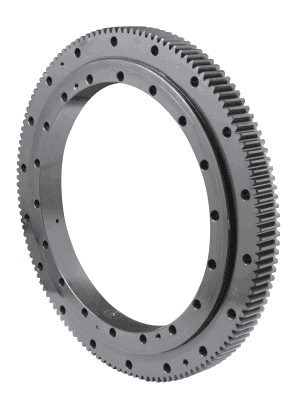

heavy-duty bearings Slewing Bearing

Slewing Bearing Rolling Element

Rolling Element Thin Section Bearings

Thin Section Bearings heavy-duty bearings

heavy-duty bearings Slewing Bearing

Slewing Bearing Rolling Element

Rolling Element Thin Section Bearings

Thin Section Bearings heavy-duty bearings

heavy-duty bearings Slewing Bearing

Slewing Bearing Rolling Element

Rolling Element